Press release -

The key role of printed circuit boards in modern electronics

Printed circuit boards (PCBs) are the basis of modern electronics. Their manufacture is a complex process that requires high flexibility, precision and cost efficiency. The world market is fiercely competitive and, as a result, equipment enters the used machinery market following factory closures. Used production machinery can provide a cost-effective solution to expand capacities and remain competitive in the market.

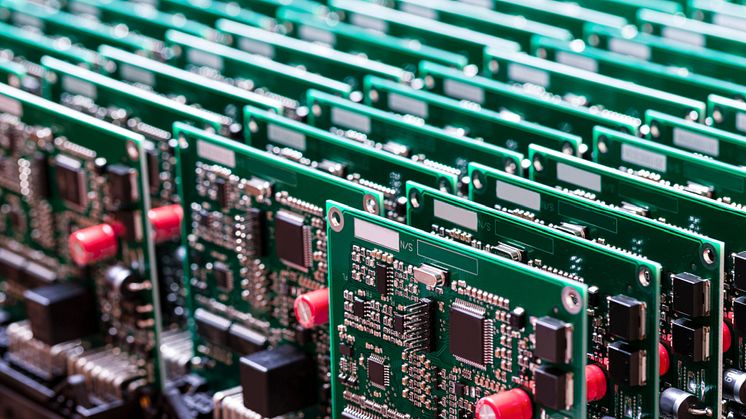

PCB stands for Printed Circuit Board. It is the heart of almost all modern electronics – from simple devices such as calculators, remote controls and digital watches to complex devices such as computers, mobile phones and cars.

On the one hand, a PCB consists of an electrically insulating and flame-retardant base. Usually FR-4, a composite of glass fibre and epoxy resin, or FR-2, a hard paper made of paper and resin, is used. On the other hand, it carries the electrically conductive traces, which consist of a copper layer, usually only 35 µm thin. On these strips, the electronic components (e.g., resistors, transistors, and capacitors) are soldered.

PCB manufacturing in series production

The production of single- and double-sided printed circuit boards is mainly achieved through a photochemical process. First, the FR board base is covered with a copper foil. The carrier plate is now drilled, and double-sided PCBs are plated-through using vias.

Next, the conductor traces are created. The desired pattern is achieved by protecting the copper intended for the track by photochemistry and chemically etching away all unwanted copper. Therefore, the board is coated with a layer of photoresist and then fitted with a photo foil carrying the negative of the board layout. The plate is exposed through the negative. The photoresist on the planned traces hardens, thus protecting the copper. This is followed by galvanising the board in a ferric chloride solution, which etches away the unvarnished copper surfaces.

The preliminary final step is the application of solder resist. To protect the conductor traces from environmental influences and to prevent short circuits caused by bridged conductors, an electrically insulating plastic, usually an epoxy resin, is used. Here, too, a photochemical process is employed, leaving contact and soldering surfaces free.

Why are circuit boards green?

The first industrial solder resist was green. For a long time, there was no alternative. Thus, people got used to the green colour, which is why it is still the cheapest and most used version.

Besides, a green colour is easy on the eyes. Until the end of the 20th century, PCBs were manually inspected by humans. Today, automated machines perform this task. However, these are also optimised for the green boards.

Global production between quality and quantity

The manufacturing of printed circuit boards is a complex process, involving more than 20 steps. Despite the effort, PCBs must be produced in large quantities and at low cost while maintaining high quality.

Thus, the PCB production market is fiercely competitive. In 2021, PCBs ranked 84th in the most traded products on the global market. The total trade reached a value of 53.4 billion US dollars, which only corresponds to a share of 0.25%: low turnover with high volume (Observatory of Economic Complexity (OEC)).

Auction after closure of a PCB production

Confronting the high-cost pressure in the PCB production, investment costs must be minimised. In this context, used machines are a good choice. They offer a cost-effective way to expand production capacity.

With careful maintenance, PCB production lines can remain operational for several decades. Especially in the production of standard boards, the technology is now highly mature and does not necessarily require the use of new machines.

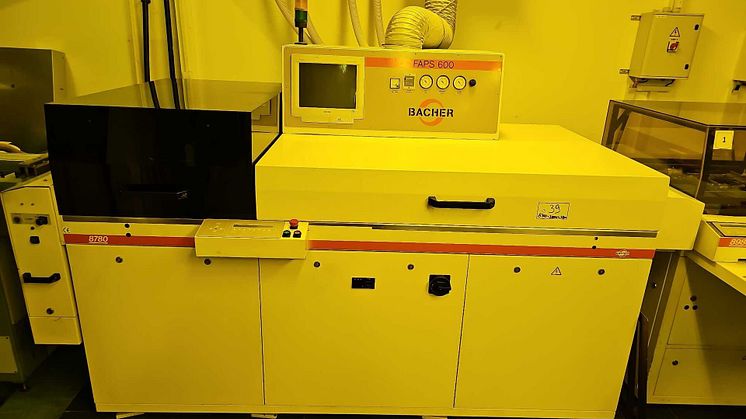

At the international industrial auction house Surplex, the equipment of a Serbian PCB manufacturer is available until 13/07. It produced high-quality single-sided, double-sided and multilayer PCBs as well as prototypes. Nearly 130 items are up for auction. The centrepiece is a Bacher FAPS 600 for automatic exposure of the PCBs and a galvanic line from PAL for etching the circuit boards. Also: exposure unit BACHER Supra light, testing equipment, CNC drilling machines (EXCELLON and PLURITEC) and accessories.

Surplex has been a trusted partner in the market for decades, with extensive experience in shipping machines and equipment worldwide. Our expertise guarantees a smooth process from purchase to delivery, regardless of the destination.

About Surplex

Surplex is one of Europe’s leading industrial auction houses and trades worldwide with used machinery and equipment. The 16-language auction platform Surplex.com records approximately 50 million-page views annually. More than 55,000 industrial goods are sold each year at more than 800 online auctions. The company is based in Düsseldorf (Germany) and has offices in 16 European countries. Over 220 employees from 20 different nations generate an annual turnover of more than EUR 100 million.