Press release -

How do tablets actually end up inside their blister packs?

41.1 million packages of Ibuprofen were sold in Germany alone in 2020. While they’re something we often have close at hand, very few people know how the individual tablets actually end up inside their blister packs. Speed, safety and affordability are a must when it comes to production. This is where used blister machines can come in.

A blister pack is a display packaging that allows the customer to see the product inside. One widespread form of blister packs is the push-through packaging used for tablets and capsules. Inside these, medication is packaged in individual doses. The advantage of this packaging is that it enables the patient to keep an eye on their medication intake.

Pharmacology – a huge and growing market

The production of medication is a growing market. This is partly due to the demographic development and the increase in age-related diseases that comes with it. Meanwhile, healthcare provision is on the rise. Half of all EU citizens were taking prescription and around one-third prescription-free medication in 2019. Willingness to self-medicate is increasing, something which is especially noticeable in the area of cold medication, which makes up the largest share of prescription-free medicines in Europe at around one-third, followed by pain medication at over 20%.

The blister packing machine: simple yet precise

Take two foils, tablets and a blister packing machine. And out comes packaged medication. It sounds simple. And it is. However, it takes extensive process monitoring.

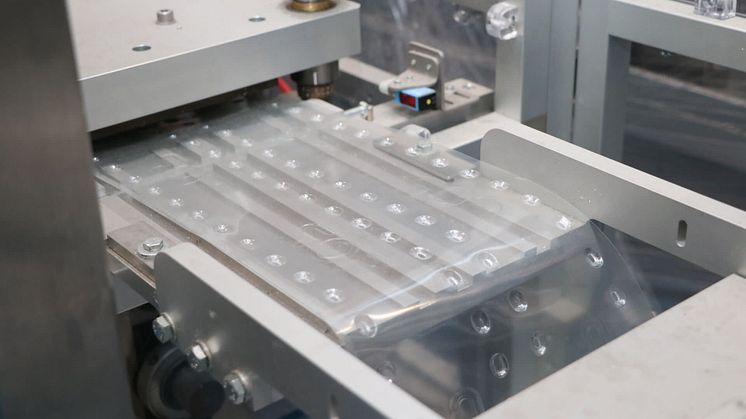

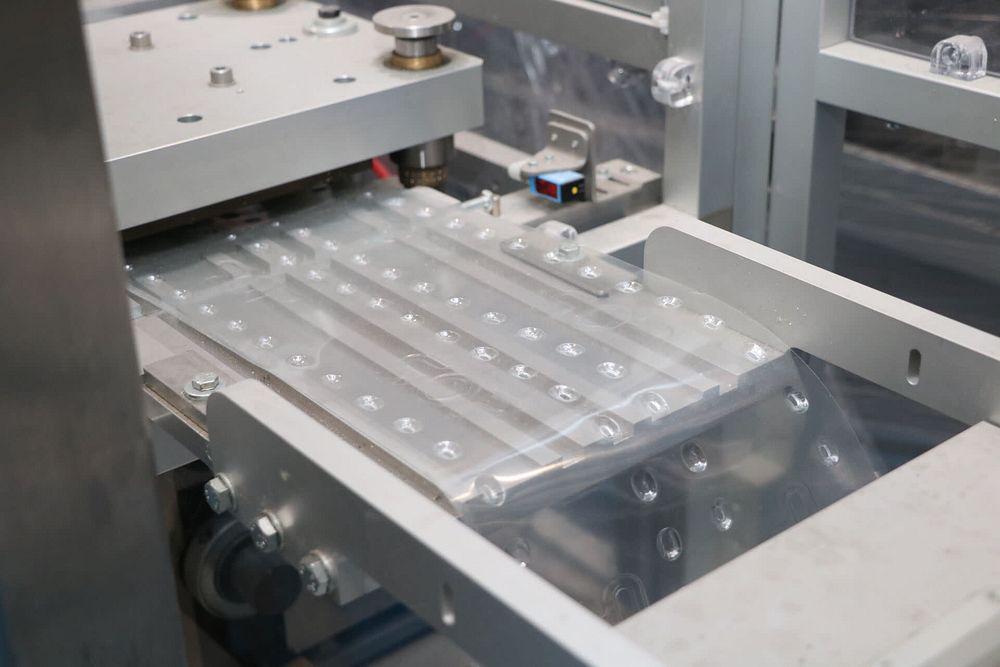

The first production step involves producing the blister moulds. These are usually made of PVC plastic or aluminium. The foil is rolled out, tightened and then pressed into the desired shape mechanically using stamps and is heat-formed if necessary. This creates a continuous foil with indentations for the tablets across its entire width.

While this is taking place, the tablets are prepared. They are carefully transported over vibrating plates or surrounding belts to prevent them becoming damaged. Any capsules stuck together are separated using brushes. The flow of tablets has to be isolated to ensure that only one tablet is sorted into each pressed cell of the blister mould foil. A camera system is used to monitor whether exactly one tablet is present in each recess.

During the third stage, the lidding foil is produced. This is usually made of hard aluminium and is just 20 µm thick. And this is the crux of the matter: On the one hand, the foil has to be so thin that medication can be removed easily. On the other hand, it also has to be so stable that the medication is protected against external influences. The aluminium foil is checked for damage while the safety system detects any micro-holes. A printer unit is also integrated into the blister machine. After all, the name of the medicine and its expiration date have to be provided on the foil.

The lidding foil is welded to the blister mould. When it comes to medication with a printed schedule, this production step needs to be so precise that the print matches the cells. One well-known example of this is the contraceptive pill, where the days of the week are printed on.

Finally, the blister packs are punched and fed out of the blister machine. The stacked blister packs are then passed onto a packaging unit, where they are packed into boxes together with their package insert.

Blister packing machines must provide maximum flexibility

The blister packing machine must enable as many different materials as possible to be processed. The blister moulds can be made of a polymer (PVC, PP, PE and PET) or a PVC aluminium composite. The lidding materials also vary depending on application, from hard and soft aluminium to a combination of aluminium, paper and/or PET.

The automated blister machines use a PLC controller to implement all packaging requests. For cost-effective blister pack production even with small production batches, a quick set-up time for pressing and punching tools is essential. The smallest tablets weigh just around 100 mg, or 0.1 g, corresponding to approximately the weight of a housefly, while large tablets can be over 2 cm long. The number of tablets per blister pack and their arrangement also strongly vary.

Speed, affordability and safety are a must

In 2021, around one-third of faulty medication in Germany was recalled due to a packaging error. A fine line exists between safety and production costs. Each quality defect poses a risk for the person taking the medication. Nevertheless, blister packing machines need to be cost-effective. Because although prices for everyday goods have been rising for decades, the opposite is the case for medication.

But prioritising cost optimisation when planning investments does not always mean you have to bite the bullet. This is because pharmacology is just another industry where you can lower your budget with the use of second-hand machines. After all, compared to new machines, used machines are much cheaper and available right away. This goes even for such specialised production systems like blister packing machines. Currently, the following three blister packing machines are available for direct purchase at Surplex.com:

- RM250 from FAMARTEC (2 units)

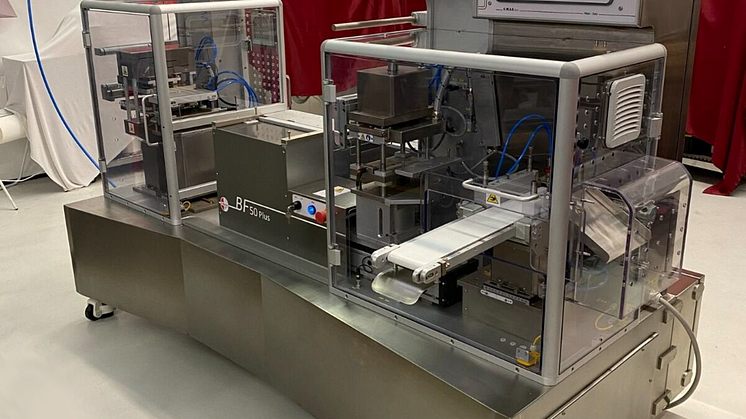

- BF50 PLUS from Omar

The systems were constructed in 2021 and are therefore state-of-the-art machines. They come from the production facilities of a cosmetics and food supplement producer in the Trento region of Italy and have been well maintained. The RM series produces up to 300 blister packs per minute and processes common materials. The latter applies to the BF50 as well. While it is smaller, it is quick to set up, making it cost-effective even for small production batches.

About Surplex

Surplex is one of Europe’s leading industrial auction houses and trades worldwide in used machines and factory equipment. The 16-language auction platform Surplex.com is visited around 50 million times every year. It sells more than 55,000 industrial products per year in over 800 online auctions. The company is based in Düsseldorf and has offices in 15 European countries. Over 220 employees from 20 different nations generate an annual turnover of more than 100 million euros.